Garbage Truck is a 40% keyboard inspired by the Cherry 1800 layout.

The first round of 30 Garbage Trucks were sold as part of a group buy in January 2021. Kits included the top and bottom case pieces, the PCB, an FR4 plate that supports all layouts, a rotary encoder, a solid titanium knob, case screws, and cork feet.

¶ Design

| Designer | Trash Man |

|---|---|

| Firmware | Trash Configurator |

| VIAL (download) | |

| Layouts | KLE link |

| Plate files | DXFs on the Files page |

| Switches | Soldered MX |

| 1x rotary encoder | |

| LEDs | 3x 3mm indicators |

| Connection | Integrated USB-C |

| Controller | ATmega32u4 |

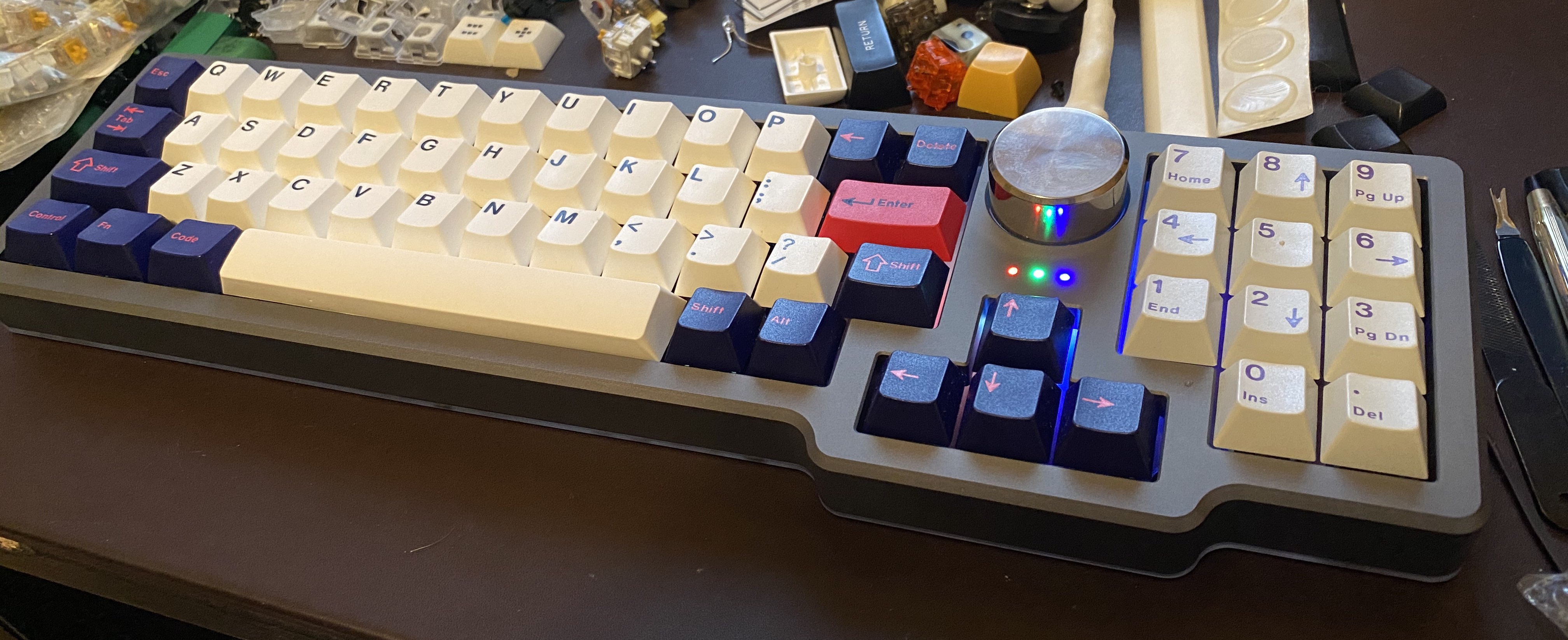

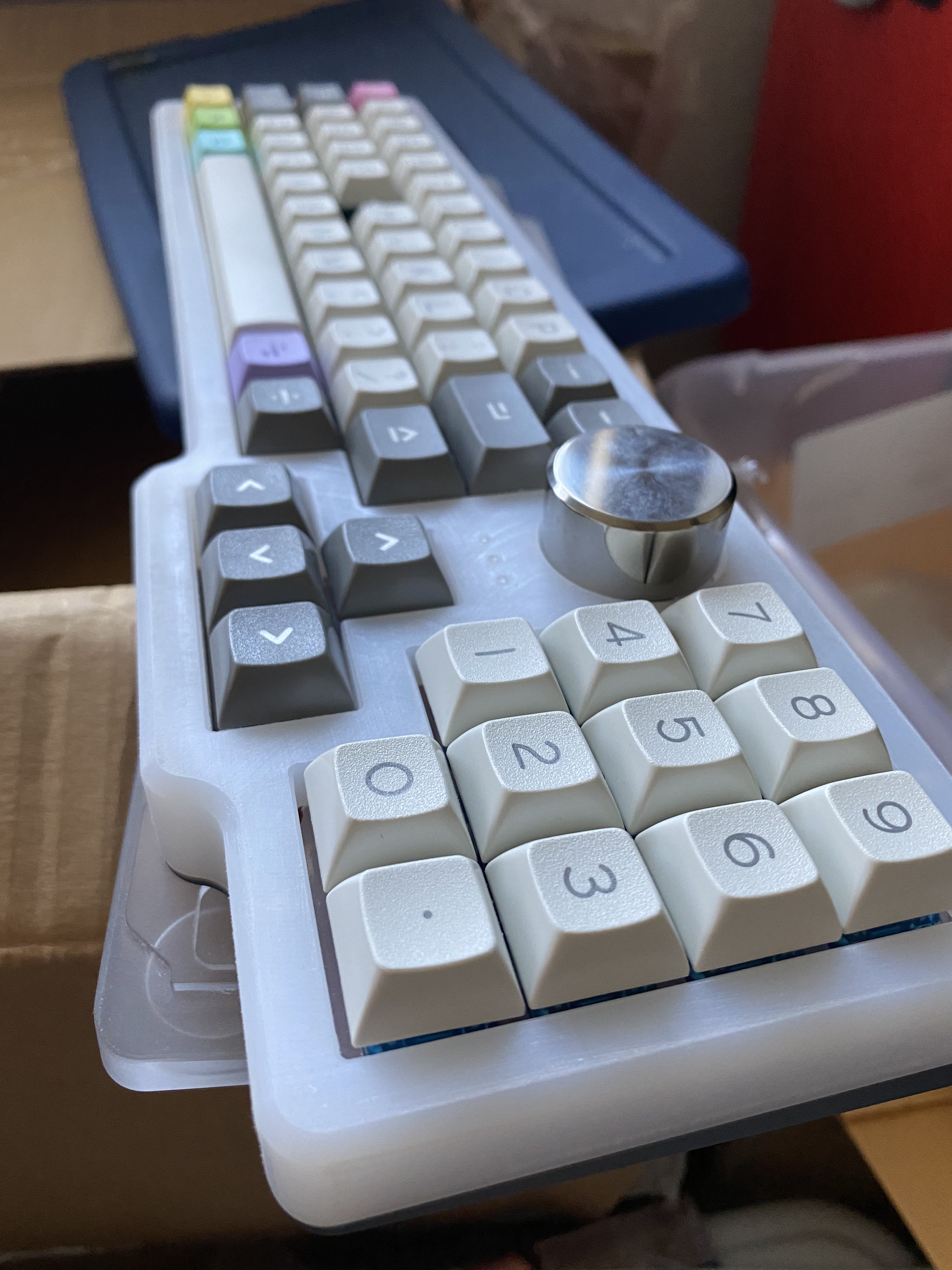

Garbage Truck is an 1800-style 40% keyboard (jokingly referred to as a 1400 layout) - meaning it is a 4-row layout with a detached arrow key cluster and numpad. It was first teased as a drawing in a photo of a Minivan posted in the gallery section of TheVanKeyboards.com. The most notable features of Garbage Truck include the large encoder knob above the detached arrow cluster, the separated numpad on the right hand side, and the exclusion of the traditional "Minivan" 1.75u Backspace key. The "alphas" section of the board is 13u wide (versus the 12.75u wide Minivan layout), allowing for the swap from 1.75u Backspace to a split 1u Backspace layout. 2u Backspace support is not included, though it can be achieved with a 2u POS-spaced keycap. The extended design also allows for a wider 1.75u Enter key (vs 1.5u on Minivan) and the addition of a 1.25u right Shift key.

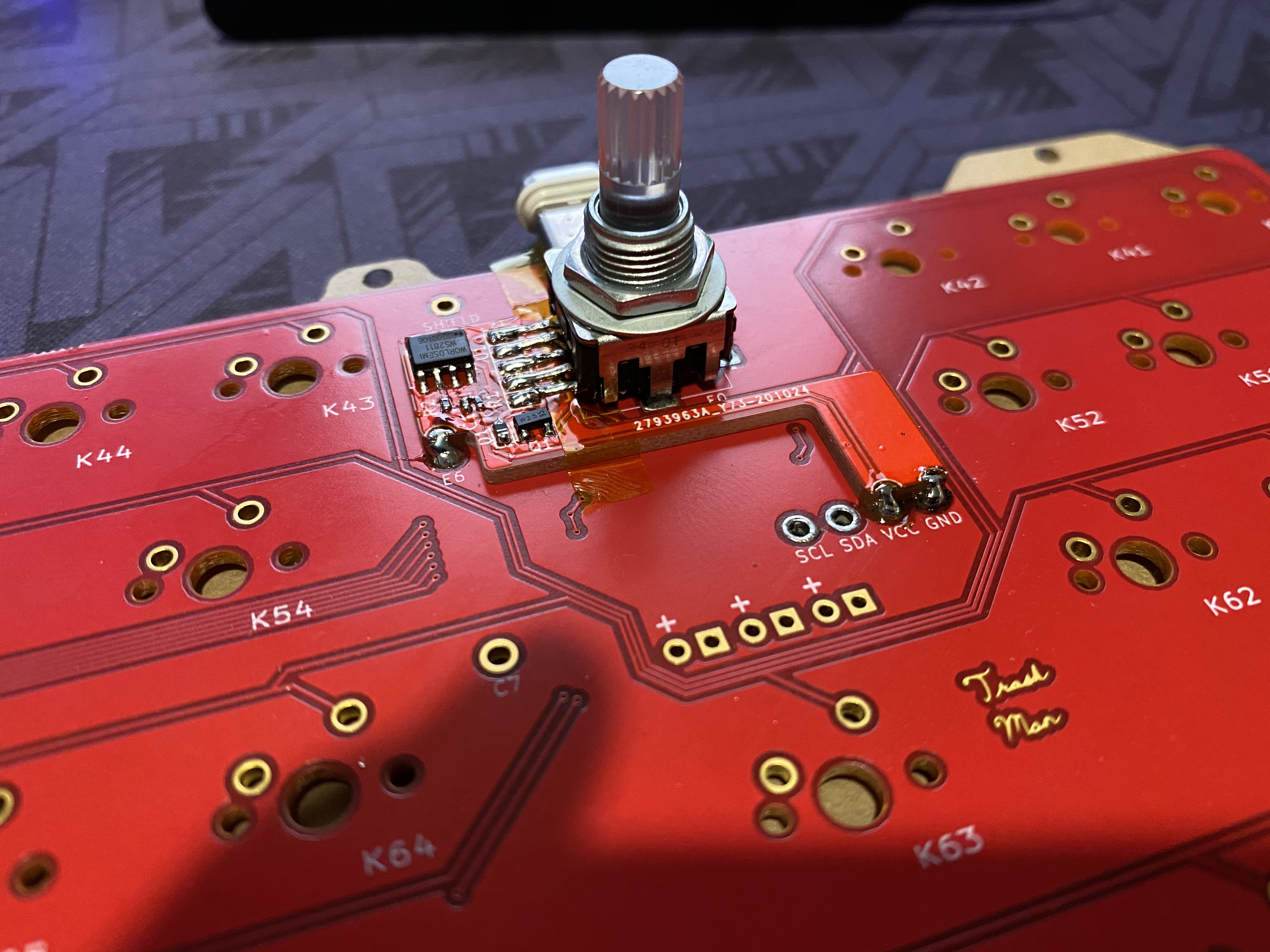

The cutout for the large knob on Garbage Truck is 30mm in diameter. The stock titanium knob that shipped with Garbage Truck boards is 29.7mm in diameter. Three 3mm through-hole LEDs are located between the arrow cluster and the knob.

The switch plate is attached to the top case piece with six mounting screws - three each along the top and bottom edges. Many users have omitted the two center screws when building their boards for additional flex when typing.

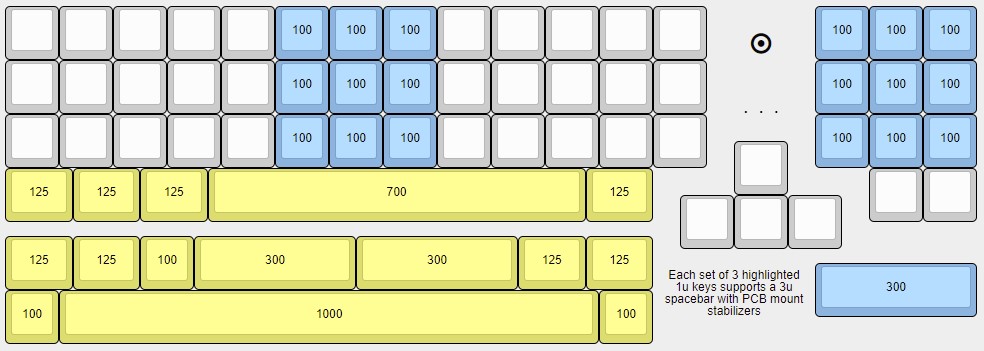

¶ Layout

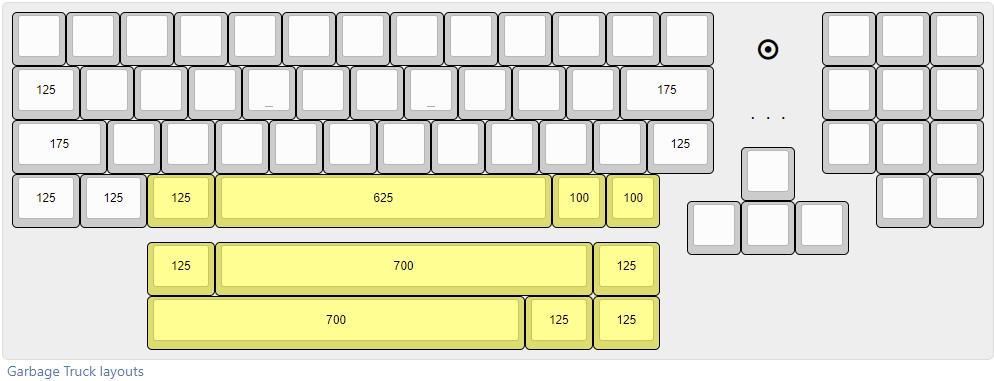

Garbage Truck supports three layouts, though two of them are just alternate placements for a 7u spacebar.

- Standard - 6.25 spacebar

- 7u - the spacebar is stretched to 7u and the rightmost 1u on the bottom row is changed to 1.25u

- 7u centered - the 7u spacebar is shifted to the left by 1.25u to allow for a centered spacebar on the bottom row

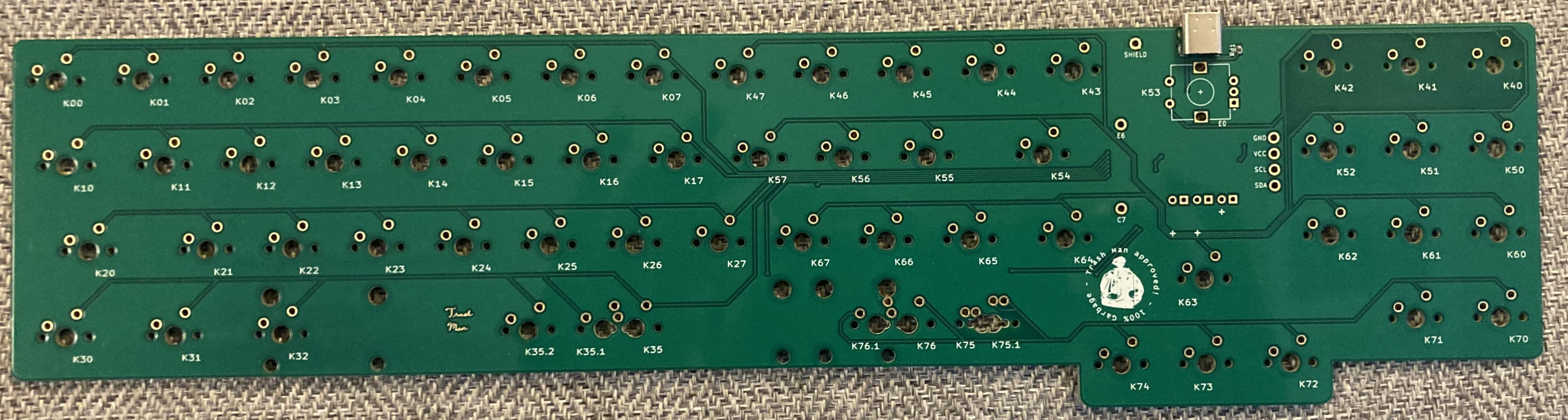

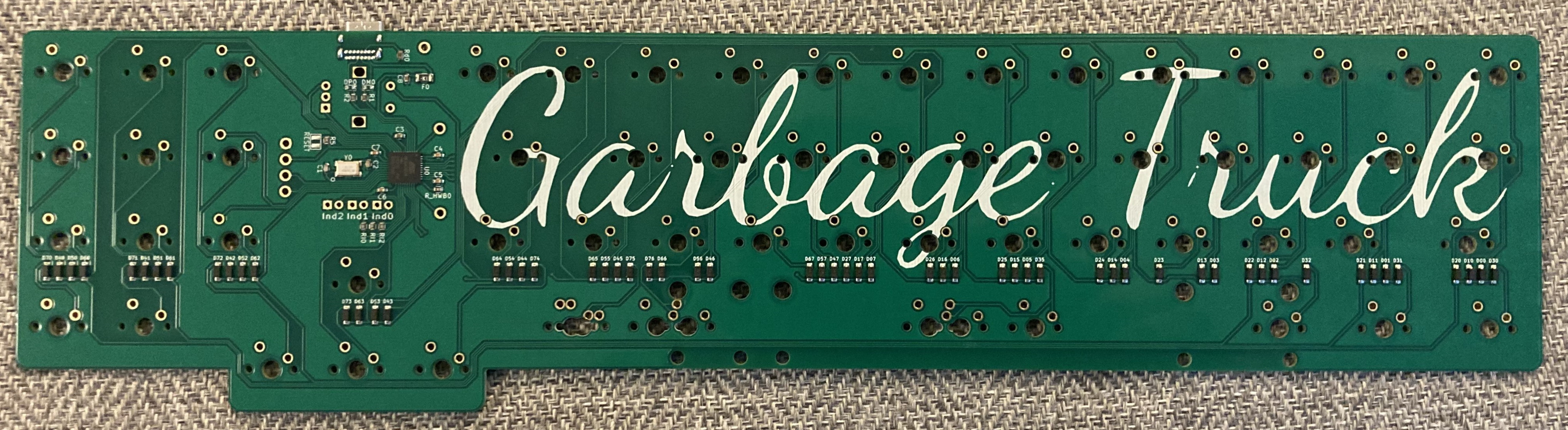

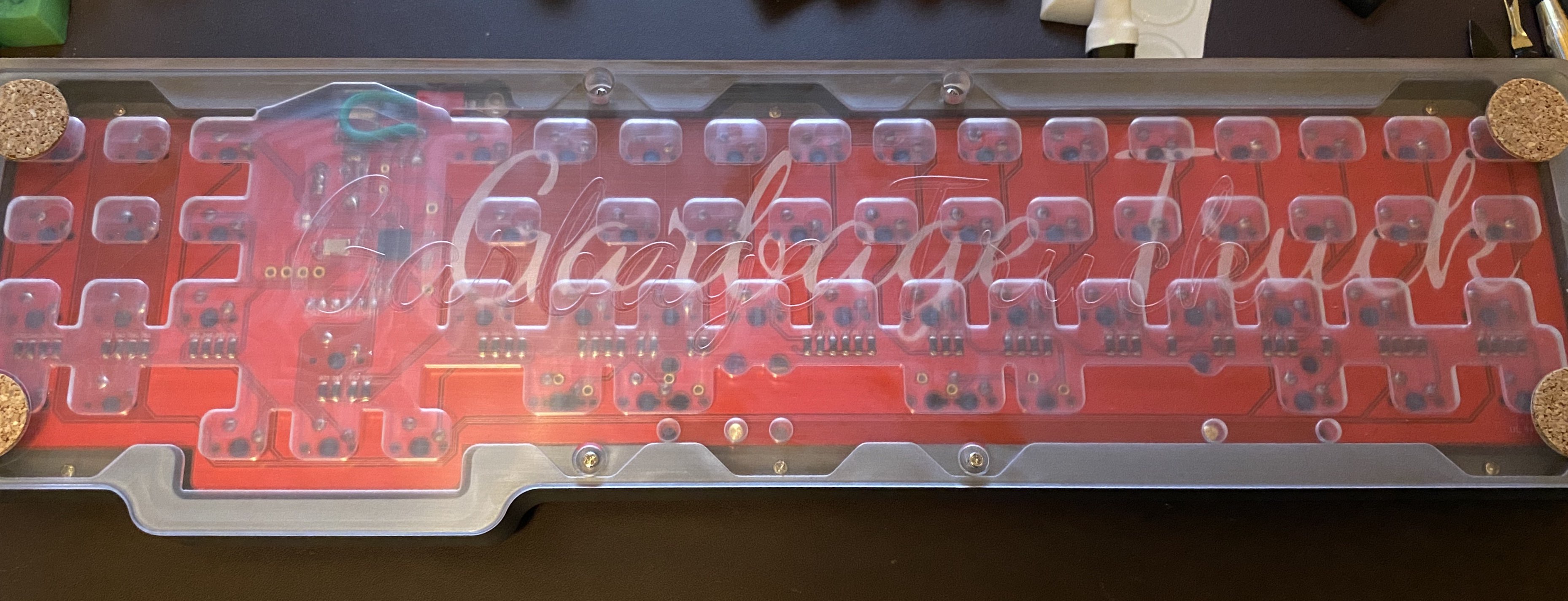

¶ PCBs

All switches are oriented in the south-facing position. None of the switch locations include through-hole or surface mount LEDs so per-key lighting is not an option. There are three through-hole indicators located between the encoder knob and the arrow cluster. The PCB includes a grounding wire that attaches to a screw in the metal top case that improves ESD protection. The USB port is located above the encoder knob. Four extra pins from the MCU are broken out between the indicator LEDs and encoder knob to support adding RGB LED strips.

¶ Prototype

Only two prototype PCBs were produced. They are covered in a red solder mask and have the name of the board written in white script across the underside of the alphas cluster.

¶ Rev 1.0

PCBs included with the first group buy are covered in a green soldermask with white silkscreen. The front of the board includes the trash bag logo with the text "Trash Man approved! 100% garbage".

¶ Community

¶ gORTHage Truck

gORTHage Truck is an upcoming, community-designed, ortholinear, drop-in replacement PCB for Garbage Truck cases. The PCB will offer several unique layouts with 3u bars as well as multiple large and split spacebar options. It is currently in the prototyping phase and a group buy has not been announced. The #gorthage-truck IC channel is currently active on the 40% Keyboards Discord server.

¶ Cases

The Garbage Truck case is a two-part top-mount design. The plate is attached to the underside of the top case piece using six tabs located on the top and bottom edges of the plate. The angled bottom piece provides a 4-degree incline. The inside of the bottom case piece includes cutouts for each switch position to accomidate flex when typing. The large encoder knob is made of machined titanium.

The encoder that shipped with the board does not support pressing/clicking the knob. A replacement encoder with a built-in push switch can be purchased here: https://www.amazon.com/dp/B07R8HVC55

¶ Prototype

Two prototype cases were produced for Garbage Truck. The first case is made of gray anodized aluminum. The second is made from milled UHMWPE top with a machined acrylic bottom. Arylic proved difficult to machine and finish with consistency across such a large piece and aluminum was ultimately chosen for the group buy cases. Parts from the two prototype cases are assembled in various configurations in the photos below.

¶ Rev 1.0

The first production cases for the round 1 group buy are made from black anodized CNC-milled aluminum. 30 total cases were produced. The surface of the large titanium knob was left raw.